The first Russian 16U CubeSat, InnoSat16, was launched into orbit on July 25 as part of a constellation consisting of nine small satellites developed by Geoscan. The satellite is equipped with a panchromatic camera that captures grayscale data within an extended visible spectrum, providing clear imagery for Earth remote sensing applications.

To assemble this satellite, Geoscan built a cleanroom — a specialized area with controlled environmental parameters. Designed for technological operations requiring minimal airborne contamination it covers an area of about 30 m2 and meets the ISO 7 cleanliness standard as defined by GOST R ISO 14644-1—2017.

After the launch of InnoSat16, the cleanroom is being used to prepare for the upcoming space missions. At present, it hosts the assembly of Lobachevsky, another 16U CubeSat developed by Geoscan for Lobachevsky State University of Nizhny Novgorod under the Space-π project. The satellite carries an optical payload of hyper- and multispectral cameras and thus requires special assembly conditions. The launch of Lobachevsky into space is scheduled for late 2025.

How the Geoscan's cleanroom is designed

The facility is built according to a zonal layout comprising three main functional areas. The first is an anteroom serving as a transition space, where personnel change into specialized cleanroom garments. Next comes an air shower, which removes any residual contamination from clothing and equipment surfaces using purified air.

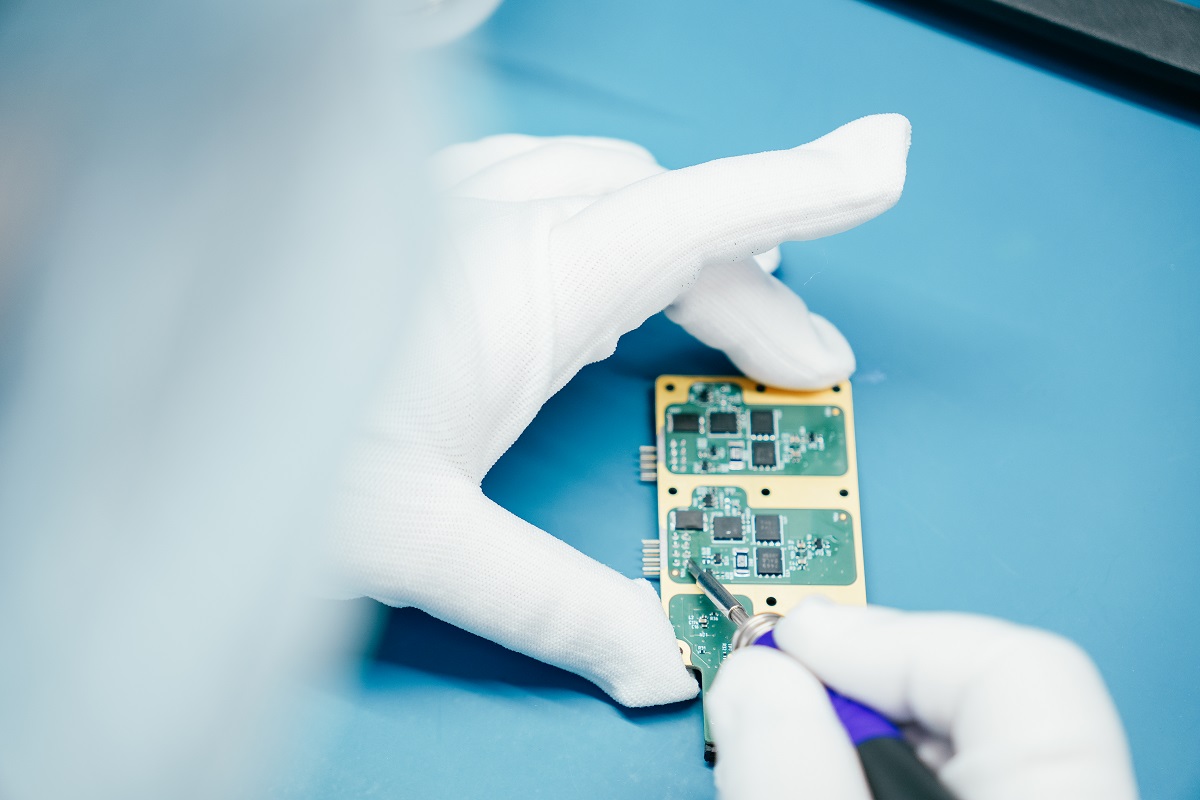

The primary working area is used for the assembly of satellites. It is equipped with antistatic flooring and technological equipment for working with high-precision optics and electronics. The ventilation and climate control system provides continuous air recirculation through HEPA filters, maintains stable temperature and humidity parameters, and ensures positive air pressure to prevent external contaminants from entering.

Every design element supports ISO 7 cleanliness compliance and meets the rigorous standards for assembling small satellites equipped with onboard optoelectronic systems.

“Building the cleanroom has been a milestone in the development of Geoscan's spaсe program. Not only has it expanded our research and production capabilities but also paved the way for large-scale projects in the field of space communications and remote sensing. We plan to enlarge the facility to support the preparation of interplanetary missions using small spacecraft — missions that could produce detailed 3D models of the Moon and Mars,” noted Vladimir Portnov, head of experimental production at Geoscan.